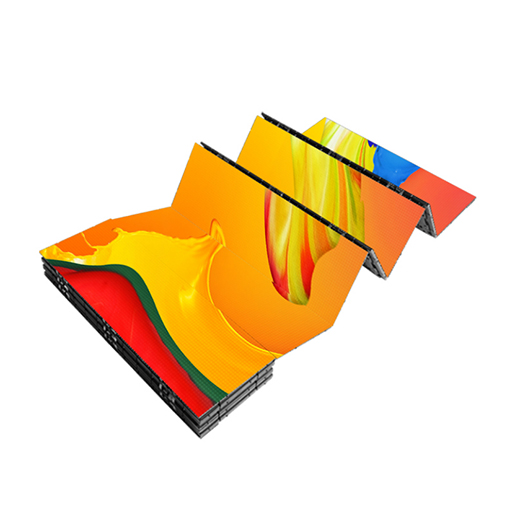

The power supply of the portable LED display screen is external and separated from the screen, making the screen slim, light and foldable.

Slim: 8-15mm

Light: 10-15kg/m2

Foldable: 360°

The dual design of soldering connector and spare plug-in connector is reliable and makes maintenance and replacement of modules easy.

Dual fixing of magnet and screw designed for modules makes the fixing and installation firmer.

The installation structure is standardized to save the installation cost and time.

Our folding LED display supports front and rear maintenance.

Prepare the "hanging beam" (hanger).

Hang the headers of all the flexible organic LED screens on the hanging beam in turn and fix them properly.

Fix the screen control boxes (power supply boxes) on the hanging beam in turn.

Properly connect the control cables between the control boxes and their corresponding screens.

Connect the whole screen power cord to the AC power supply.

Connect the whole screen signal wire to the transmitting box.

Adjust the spacing between each two screen modules, and connect each two screen modules with four-corner connecting sheets to ensure seamless splicing.

Power on, light up and debug.

Prepare the mounting frame that can be absorbed by the magnet for installing the screen.

Attach each foldable LED to the mounting bracket in turn, and fix the screen to the mounting bracket with screws if necessary.

Place the electric cabinet or control box in a safe place.

Connect the control line between the electric cabinet or control box and the screen.

Connect the whole screen power cord to the AC power supply.

Connect the whole screen signal line to the transmission box.

Adjust the spacing between each two screen modules, and connect each two screen modules with four corner connectors to ensure seamless splicing.

Power on, light up and debug.